Does your amplifier have a level indicator?

Have you always envied the fancy amps with LED level bar graphs?

Would you like to build your own STEREO LEVEL INDICATOR?

he complete kit can be purchased from Talking Electronics.

To place an order, click: Stereo VU Meter kit

To place an order, click: Stereo VU Meter kit

This is it. It's a STEREO LED LEVEL METER. It's the cheapest and best bar graph display available and best of all, it uses readily available components. You only need a handful of LEDs, 22 transistors, some resistors, diodes and a set of electros - it doesn't require any chips. You may be wondering why we didn't choose the LM 3914 or LM 3915 bar-graph LED driver chips. The reason is simple. We learnt our lesson from our Mini Frequency Counter Book. In it we used a relatively novel chip, the CD 4026. And after releasing 10,000 copies of the book, with printed circuit boards attached, the chip became almost unobtainable in Australia. This proved to us that many of the readers were making the Mini frequency Project. Now, a chip such as the LM 3914 is scarce at the best of times. Can you imagine what would happen if we used it in a project? Ninety per cent of the readers would miss out. This means we must confine our projects to readily available components and avoid rare items, no matter how inviting they look. We compared a LED level meter using the chip with our unit and the difference was negligible. Both had the same quick response-time and about the same readout values on the line of LED’s for the same input signal. But the big difference is in the cost of construction. By using transistors, you will save $4 over the cost of two chips. If you don't mind the additional time required to fit the extra components, the $4 is a valuable saving and by using discrete components, you can build it from parts you may already have in stock. |

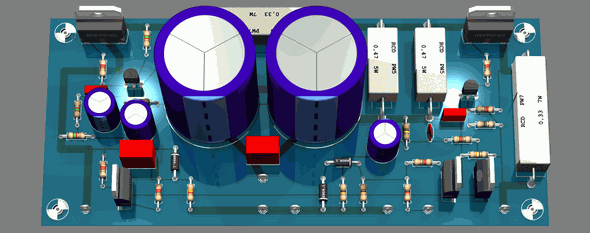

The Stereo VU Meter PC board with the components fitted. Only the battery and speaker are external, connected to flying leads.

|

| A close up of the completed unit. The overlay makes construction easy. Make sure the left-hand row of resistors starts with 47k at the bottom and 4k7 at the top. I saw one unit with the whole row reversed. It made very little difference to the performance of the unit, but it was not quite as sensitive as the correct version. |

The BAR GRAPH section of the Stereo VU Meter circuit. The "front end" section is below:

|

| The BOOTSTRAP circuit connects to the LED bar graph via A B C. Only one BOOTSTRAP circuit is provided on the board. It is capable of driving both bar graphs in a mono mode. For a stereo readout, you will need to build another bootstrap circuit. This will give a STEREO SOUND LEVEL INDICATOR. |

The Circuit

The circuit basically consists of two identical channels feeding two rows of LED’s. A highgain bootstrap front-end is also provided to allow the board to be coupled to an inbuilt speaker/microphone which will give a mono readout of the sounds being picked up. A mini trim pot is provided to set the sensitivity. This makes the project completely portable and it can be used as a SOUND LEVEL meter in a disco or other noisy situation. To give a read-out in dB it would require calibration. The simplest method of calibration would be to compare it with a commercial unit and give each LED a value in dB. If you build another bootstrap circuit, a portable stereo sound detector can be made. It will be able to compare sound level in different parts of a room or compare the relative outputs from 2 speakers. As designed, each stereo section can be connected across the terminals of a speaker and the unit mounted in some prominent place for an eye-catching display.

Construction

Before you begin, lay the components on the work-bench in a position relative to that on the PC board. Some of the parts have the same value, such as the 330R resistors. These should be positioned on the board with their tolerance bands all around the same way. Separate the two BC557's from the other two transistors and be sure you can identify the 22u electrolytic from the 4.7u. The board looks deceptively simple because most of the components are placed in rows. It will take at least one and half hours to construct the project and the most important point throughout construction is to create a neat appearance. This means aligning each component with the next and keeping the heights all the same. Otherwise the neat appearance will be destroyed. |

| The Stereo VU Meter printed circuit board |

| The suggested method of construction is to start with the resistors and diodes. These should be inserted alternately as required by the board so that you have maximum room when placing them in position. Slow and sure wins the race. It is best to insert the parts one at a time and push them firmly onto the board. Nothing looks worse than a mass of floating components, some high, some bent this way, others bent the other way. Once you push them onto the board, bend their wires outwards so that the component is held in position. Turn the board over and solder the two connections quickly. Check that the component has not shifted, then snip the two wires. Continue down each row, adding one item at a time. If you find you are closing over some of the holes with solder when you are soldering, I suggest you only tack-solder the leads and wait for the other component to be inserted, before finishing the joint. Tack-soldering is very fast and requires almost no solder. This prevents the solder flowing over other lands and filling up the holes. You may have noticed that the two channels are a mirror-image of one-another. This means the cathodes of the LED’s face outwards and before inserting each LED you should look into their opaque body to make sure they are being inserted correctly. In our prototype, the two top LEDs of each channel are a different colour, mainly to add interest to the display. You may choose to add another colour for the bottom two or three LEDs and produce an even more exotic display. The driver transistor for each channel and the bootstrap circuit fits onto the right-hand end of the board. All the component values are identified on the overlay and the two BC557's are shown as 'filled in', whereas the BC547's are open 'D's'. There are no jumpers on the board. However we have made provision for connecting the bootstrap circuit to either one or both channels via one or two links. These links are taken from the 'pre-amp OUT' point to either the left hand channel or the right hand channel. |

The Stereo VU Meter Kit

|

PARTS LIST:

|

| 18 - 330R resistors 2 - 470R 1 - 1k 1 - 2k2 5 - 4k7 5 - 10k 2 - 22k 2 - 33k 4 - 39k 4 - 47k 4 - 4.7mfd 16v PC electrolytic 2 - 22mfd 16v PC 20 - BC 547 transistors 2 - BC 557 transistors 18 - 1N 914 or 1N 4148 diodes 14 - 5mm red LEDs 4 - 5mm green LEDs 2 - 100k mini trim pots 1 - 9v battery snap 1 - speaker 8 ohm 1 - VU METER PC board |

HOW THE CIRCUIT WORKS

The VU METER consists of 3 sections: 1. BOOTSTRAP CIRCUIT 2. BUFFER TRANSISTOR 3. STAIRCASE VOLTAGE DETECTOR

The BOOT-STRAP circuit is very successful at allowing a dynamic microphone in the form of a 2¼in speaker to detect small sounds and have them amplified sufficiently to be fed into a normal amplifier.

The BOOTSTRAP is rather unique in its operation. It uses 2 directly coupled NPN transistors wired in a similar mode to cascade to give an enormous gain. In our prototype we measured this to be about 1,000 times! In the quiescent condition, the transistors in the bootstrap circuit are slightly turned on. This means they will accept a few millivolts from the speaker and turn the circuit on harder or turn it off. During quiet conditions 2 millivolts is developed across the speaker due its resistance of 8 ohms. Take the case where the speaker produces 2 millivolts which is in phase with the quiescent voltage. This will turn the lower transistor slightly off. The collector voltage will rise and in doing so, take the base of the top transistor with it. The top transistor is partially an emitter-follower. Under normal circumstances, the collector voltage of the top transistor would rise about .2v. This will make the emitter voltage of the top transistor rise .2v (which is normal for an emitter follower). Now the top 22u electrolytic will transfer this .2v to the join of the 10k and 2k2 resistors and cause the top transistor and turn it ON further. This action feeds around the transistor until the transistor can rise no more. The top 22u was previously charged and some of its voltage is lost through the 2k2 resistor. This reduces the base voltage and the transistor begins its downward excursion. I have taken the extreme case. If the first transistor does not turn on to quite the same extent, the emitter-follower will rise until the loss from the top electrolytic prevents the transistor from rising any more, and it begins to fall. The lower 22u prevents this swing from appearing on the base of the lower transistor. It acts as a damper. The output from the BOOTSTRAP can be as high as 2v p-p and this is ample to drive the buffer stage. In fact the signal needs to be attenuated by a pot so that the range can be set according to the amplitude of the input signal. The 470R resistor in series with the pot is only needed when the VU Meter is connected directly across speaker lines. The BC557 is not an emitter follower. Don't get confused. It is wired as a normal common emitter stage for a PNP transistor. Thus it will provide a high gain in this situation. The AC voltage appearing at the wiper of the 100k trim pot will pass through the 4u7 electrolytic and become rectified by the 1N4148 diode. With no signal present, the voltage on the base will be 9v. As the input signal increases, the voltage on the base will drop to 8.35v and this is sufficient to turn the transistor ON fully. The voltage on the collector will range between 0v and 8.5v. This voltage is stored in the lower 4u7 and applied to the chain of 8 diodes. The 4u7 dictates the decay rate and gives the LEVEL METER its rapid attack, slow decay characteristic and allows even brief peaks to be detected. To reduce the decay time you can increase the electrolytic to 22u and this will keep the LED’s illuminated for a longer period, similar to the commercial units. Between each diode is a high value resistor. As the voltage rises to about .6v, the first transistor turns ON. At this stage the voltage on the cathode of the first diode is 0v since the .6v has been dropped across it. The voltage needs to rise to about 1.2v before the second transistor turns ON. This continues down the line with each transistor turning ON at its allotted voltage level. The set of 330R resistors limit the current through the LEDs to a safe value and the base resistors serve as a voltage dropper so that the base will not be forced to go higher than .6v. The number of transistors which can be operated in this Staircase arrangement is limited by the battery voltage available since each transistor and diode will take .6v from the voltage. TESTING To test the stereo VU meter, connect the two links as shown on the board and connect the dynamic microphone (speaker). Solder a battery snap to the board and connect a 9v battery. This project is now a self-contained level meter and will give a dual readout of the sound detected by the speaker. We are using a small speaker as a microphone as we have had a great deal of success with its sensitivity. No calibration is required. You only need to position the pick-up (spkr) near a radio or stereo that is playing at normal listening level and adjust the sensitivity controls. These are the two 100k mini trim pots in the buffer stage. First you must set each one so that the top led is just illuminated when a loud passage is being received. Then you need to trim the two displays so they produce equal readouts for the same information. FAULT FINDING Since each channel is identical, you will be able to reference off one channel to repair the other. The ‘chain of transistors’ are all DC coupled, and you can test their operation by using a 10k resistor connected to a set of jumper leads. Connect one jumper to the positive of a battery and touch the other onto the cathode of the lowest diode in the staircase. You cannot do any damage to any component when probing around either channel and I suggest you take this opportunity of seeing the effect of a turn-on voltage when applied to a set of transistors. When the 10k resistor is touching the cathodes, almost all the LEDs should light up. By moving the resistor up the chain, the top LED will light. This will show the channel to be functioning and you should test the other channel for the same effect. If one LED fails to light, you may have a base-emitter short in one of the transistors or the LED itself may be faulty. If any LEDs above number 6 fail to light, one of the diodes may be open or you may have a dry joint. If you have trouble getting one channel to function, you can use the components from the other channel as test pieces. This is the great advantage of having two identical channels. But by using parts from the good channel, you could finish up with two bung channels. That's the risk you take. The buffer transistor can now be tested by connecting the 10k to earth and touching the other end on to the base of the BC557 transistor. This will illuminate one complete row of LEDs. The remainder of the circuit is AC coupled via the 4u7 electrolytic. Only the DC conditions of the bootstrap section can be tested with simple equipment. Use a multimeter to detect voltages similar to those given here: |

BOOTSTRAP VOLTAGES

|

| Both transistors will be turned on very slightly and because it is a very high gain circuit, you cannot remove one transistor and hope to get a smaller amplification. It will completely fail to work.Here is an application by Gerry Holt: He attends live music events in pubs and clubs. These "open mic" events enable anyone with an act or instrument to put on a 15 minute performance. To curb the enthusiasm of some 'artists' and reduce the pressure on the organisers, I saw the need for a visible indication of the noise level in the room. I built the Stereo VU Meter and mounted the LEDs separately and fitted a tube over all the components. I painted the tube to make the whole project look impressive. It worked so well, those running the event were ecstatic. The tube is closed at the top and bottom with jam jar lids, the base lid having sufficient clearance to house the battery (on a clip) and a small power switch. The mesh allows the sound to reach the microphone (the speaker acts as a dynamic microphone). |

Không có nhận xét nào:

Đăng nhận xét